FEATURES

Say goodbye to limitations and hello to a new level of efficiency and productivity.

The finishing system series powered by double plotters is the ideal solution for those who choose the knife cutting technology with faster delivery for their jobs.

These systems designed with a desktop and short footprint look, allow you to cut different types of paper and plastic films in any shape, size and quantity with a very limited waste of media during the loading process allowing the opportunity to run also very short run jobs.

Being a digital workflow, no extra costs for die plates are involved.

Being a digital workflow, no extra costs for die plates are involved.

The main reason to own a label finishing system is to acquire the independence and flexibility to run label productions on demand with the freedom to change the shape, size and quantity for each single job every time.

Blank labels always on TOP

Both finishers can also run in blank label mode, working synchronized and keeping the required gap constant.

Through the software it is possible to set each single parameter in just a few clicks.

Brochure |

User Manual SCR35X2 | User Manual SCR35X2 REV.01 / REV.02 |

User Manual VRG22X2 | User Manual VRG22X2 REV.01 / REV.02 |

-

-

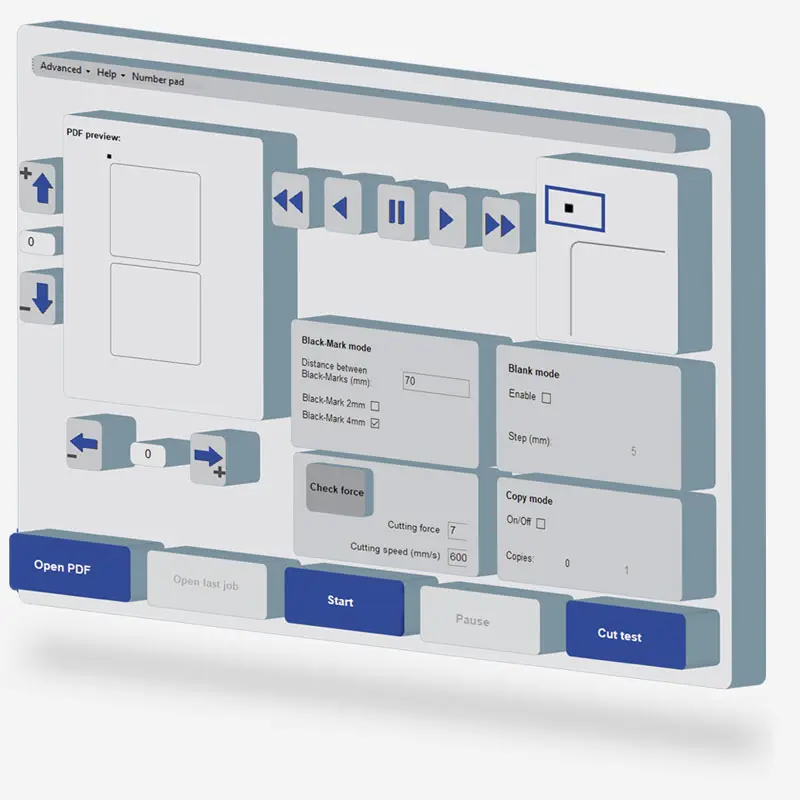

Cutting manager software

The cutting position is synchronized by using an intuitive software and CCD cameras to detect the single registration mark inside each layout, which can then be adjusted through the offset settings.

Importing a PDF cutting file to begin this process simplifies the workflow with an added benefit of tracking each completed job and viewing the daily working reports that are auto generated by the system.

-

-

Knives management will not be a nightmare

With DPR systems, both plotters will always be running for any type of application.

This means that the wear on the cutting knives will have close expiration date and it provides consistent cutting quality along the entire job.

On the two heads equipment in several conditions it is mandatory to use one head only, so the usage of each head is different and the knives wear is completely different.

As consequence, it happens frequently during the jobs using the two heads to obtain different cutting qualities because the knives run out with different timing, it means a waste of time for the operator to supervision the job and waste media when the cutting result is not consistent.

| THE LAYOUT CONTAINS DIFFERENT SHAPES |

| THE LAYOUT CONTAINS DIFFERENT SIZES |

| THE WIDTH OF LABEL REACHES THE MAXIMUM MEDIA WIDTH |

| UP TO 8 M/MIN (depending on job settings) |

| BLANK LABELS ALWAYS ON TOP |

For all the above scenarios the two heads on the double plotter are always in action while on the double head system, one head must be disabled.

| VRG22X2 | SCR35X2 | |

|---|---|---|

| Input / Output Roll Diameter | 7.87" (200mm) | 9.84" (250mm) |

| Minimum Web Width | 4.34" (110mm) | 4.34" (110mm) |

| Maximum Web Width | 8.86" (225mm) | 13.77" (350mm) |

| Maximum Cutting Width | 7.87" (200mm) | 13" (340mm) |

| Minimum Slitting Width | 0.75" (19mm) | |

| Minimum Label Length | 0.39" (10mm) | |

| Maximum Label Length | 13.77" (350mm) with limitations | |

| Lamination Module | YES (optional) | YES |

| Number of Slitting Blades | up to 8 | up to 12 |

| Maximum Media Thickness | 0.25mm (10 mil) | |

| Maximum Cutting Speed | 600mm/s (24 in/s) in all directions | |

| Roll Core Size | 3" (76mm) | |

| Warranty | One Year Parts and Labor. Usage Limitation may apply | |

VIDEO